Among other applications EMW® has supplied gas turbine air filters to the power generation industry since the mid 1980's. In the late 1990’s we expanded our product range by adding (H)EPA air filters. Today our advanced OEM and replacement filters are used in gas turbine power generators worldwide. Whether your plant is a peaker or a base-load station, we can upgrade your gas turbines' performance with expertly engineered systems and solutions made up of our coalescers, pocket filters, filter cells, (H)EPA filters and other high-performance components.

Inlet air quality is a make-or-break factor for gas turbine performance. Intake of particulate-laden air into a gas turbine causes fluctuations in power output, resulting in headaches for power plant operators.

Inlet air quality is a make-or-break factor for gas turbine performance. Intake of particulate-laden air into a gas turbine, especially under extreme environmental or industrial conditions, causes fluctuations in power output and resultant headaches for power plant operators.

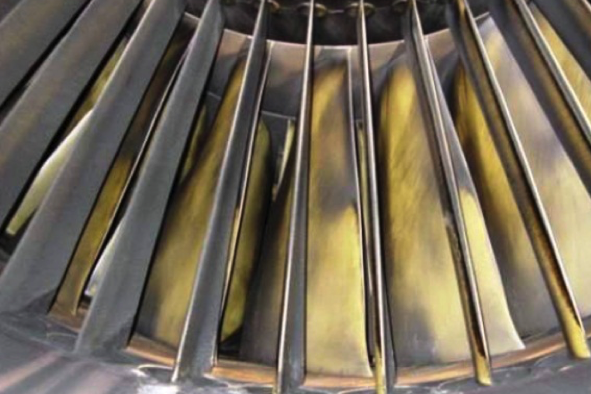

The underlying cause of the problem is compressor fouling. In such cases operators often look to on-line compressor washing as a quick fix to restore power and efficiency. The success of this measure is short lived as on-line cleaning simply washes contaminants from the front blades to the inner blades of the turbine. Shutdown of the turbine permits much more effective washing but causes costly downtime. In any event, the capacity loss comes back again due to the ongoing contamination which continues to build up and damage blades and other components.

The best solution is to address the problem at its roots, i.e. to remove particulates and dust particles from the inlet air before they even get trough the gas turbine filter house inside the turbine. This calls for use of improved filter systems providing higher filtration efficiency.

Contact our team for assistance in gas turbine filtration and finding new power plant filters.

Power capacity loss can be avoided in turbines operated with the installation of an efficient gas turbine air intake system. The arguments most often heard against higher filtration efficiency are increased pressure drop across the filter system, reduced filter service life and increased costs. None of these are an issue if the filter system is designed correctly for the gas turbine, operating environment, process conditions and maintenance intervals in the application at hand. In many cases the filter system can be upgraded without any modification of the existing gas turbine filter house. The upgrade, although requiring investment costs, provides a variety of cost savings and other benefits including:

Are you intereseted about our technology? Open questions left? Contact our team for assistance with efficient gas turbine filtration!