Scroll down

When Gustav A. Emmerling and Werner H. Weyl saw the opportunity to open up a new market for the then still very unknown foam from the USA, they pulled out all the stops. In 1954 they founded EMW (EM=Emmerling, W=Weyl) and imported the special plasic to Germany.

Here the foam was first processed into insulation material and for various everyday objects. At that time, they could not have imagined what other potential the foam had.

In 1977 the company moved away from Hahnstätten, where it was founded and moved to Diez. This beautiful new home with first‐class transport connections left a lot of room for expansion and progress. The journey could continue from there.

The subject of ‘Filtration’ took its course, among other things boosted by the reticulation of the foam. The open‐cell foam paved the way for many new application areas in filtration. The filter foam owes its brand name to the innovative process for opening the pores “Poret®”, which actually stands for “pores reticulated”.

Result of the reticulation: The previously closed foam pores are now open‐celled.

In 1984 EMW filtertechnik entered into Minipleat processing technology. With this technology it is possible to integrate a larger area of filter medium in a compact size. Currently, in air filters with a compact dimension of approx. 60x60x30 cm filter areas are being built in which are comparable to a 40 m² apartment.

This type of air filter enables users to separate efficiently even particles < 1 µm (a range of particles in which viruses and bacteria are present). In addition, the energy consumption is more efficient.

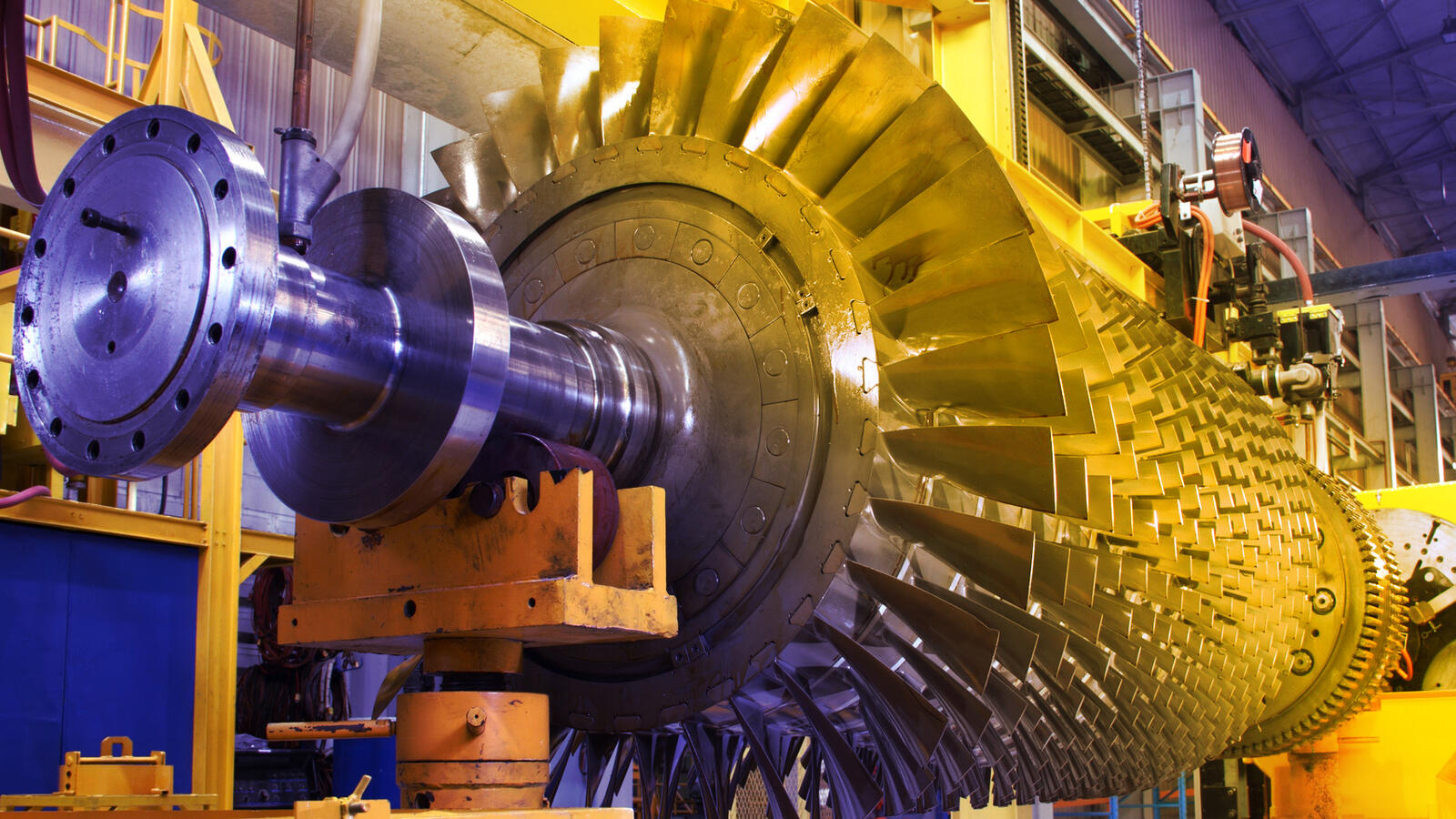

Every end is also a new beginning. A century was drawing to a close and at the same time it was the

beginning of an important milestone for EMW

®

: the entry into the GT market. With the gas turbine

manufacturer Siemens as a customer, the decisive step was taken.

Thereafter, pioneering work followed, because EMW® installed the highly

efficient

HEPA filters in the power station sector already in the 90s which not only brought the advantage of a

significant performance optimisation. The CO2 and fuel reduction also ensure a more ecological

footprint.

In this decade, the chapter on capacity expansion is being advanced under the direction of Karl‐ Dieter Begeré.

Source: Google Maps

Today around 120 employees at the headquarters form a strong and well‐coordinated team,

including 6 apprentices. In addition to the apprenticeship to

be an industrial clerk, since 2020 there have also been training positions for machine and system

operators, IT specialist systems integration and marketing communication.

EMW® can proudly look back on obstacles it has overcome and celebrate successes. Thanks to an international network of representatives, the filter experts are already operating in over 60 countries. Their filtration solutions remain firmly “Made in Germany”.

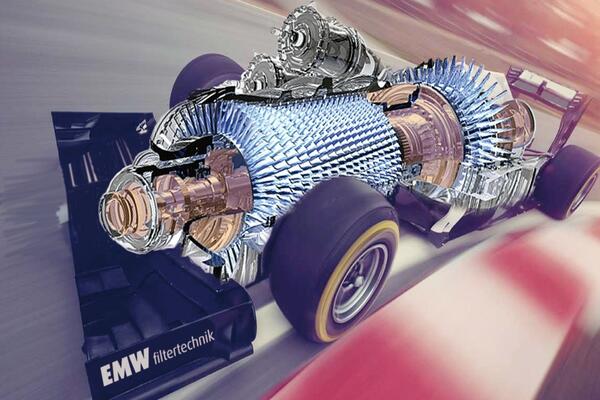

A large number of applications, such as the supply air filtration for gas turbines , as well as air conditioning / ventilation technology and biological wastewater treatment have long been part of

the repertoire. However, there is only one question left: What does the future hold?

|

Apprentices, students on dual study programs & trainees at the apprentice meeting 2022