The power output capacity of a gas turbine normally declines gradually over its service life. Surface deposits in compressors, better known as fouling, cause roughly 70 – 85% of capacity loss in gas turbines.

So how can a better protection of the compressor be achieved? One method for avoiding the fouling is on/offline washing, a method which provides only short-lived recovery of capacity. Therefore, a higher filter efficiency is required, although the question arises in the minds of design engineers: Are the advantages provided by finer filtration a bad trade-off when weighed against the increased pressure drop it causes?

,,Surface deposits in compressors cause roughly 70 – 85% of capacity loss in gas turbines."

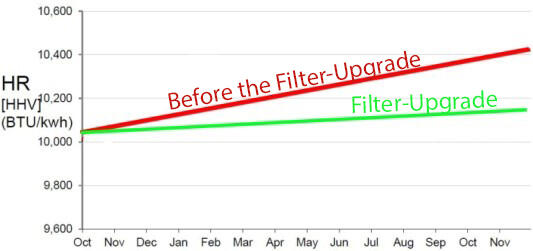

Capacity decline in a Combined Cycle Power Plant with 2 SIEMENS SGT5-4000F gas turbines located in Southeast Asia. Running in base-load operation, each turbine has a nominal electric power capacity of 244 MW.

In the existing configuration, the coalescers were changed every 4 months, the prefilters every 12 months and the fine filters every 3 years of operation. Although every-thing in the system seemed nor-mal at first glance, a look behind the scenes at filtration efficiencies conveyed a totally different picture.

The original system achieved an overall filtration efficiency of ap-prox. 35%. Analysis of the filter house air showed an average par-ticulate throughput of 750 kg (1650 lbm) per year with particle sizes primarily smaller than 0.4 microns.

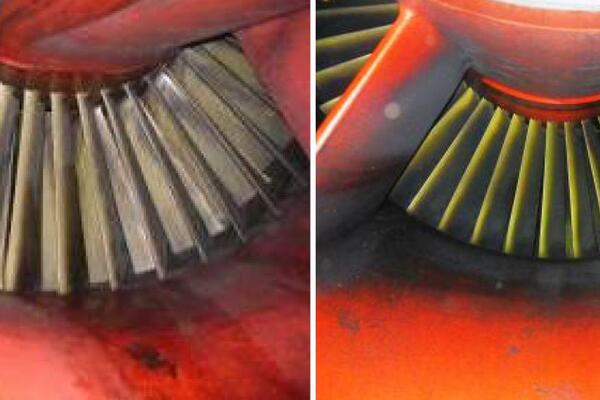

Figure 1.2 shows the severe foul-ing build-up encountered with the existing filter configuration. The filter system did not provide the required efficiency, allowing fine particles to enter the gas turbines in large quantities.

In an effort to address the prob-lem, the turbines were washed offline 3 times over a 120 day peri-od. The washing provided no last-ing benefit; fouling with the same severity as before returned shortly after each washing. This effect was mirrored by the turbines' power capacity, i.e. a temporary im-provement in capacity which quick-ly disappeared.

The upgrade included a changeover from Class F7 fine filters to EMW® (H)EPA Class E12 fine filters. The EMW® filters provide convincing benefits by removing virtually 100% of even the finest-sized particles with only moderately increased pressure drop over the filter lifespan.

Capacitiy loss: The capacity loss observed in the gas turbines was due to dusty inlet air. The severe surface fouling on the turbines' inner surfaces was particulate matter which had settled and accumulated there.

The EMW® Upgrade: The filtration performance in the inlet air system was improved by upgrading the filter class from F7 to (H)EPA E12, i.e. a jump upwards of 5 filter classes. The EMW® filter version used was MPK 4 12-31 GT.

The prefiltration stage was also enhanced. The Class G4 coarse dust filters previously in use here were replaced by EMW® Class F8 fine filters, selected specifically to best protect the (H)EPA final filters and prolong their service life. The coalescer stage for coarse dust removal replaced by the Poret® coalescer media. The upgrade did not require any modification of the filter house structure.

Service Life: The (H)EPA E12 final filters in the upgraded system provide a useful service life of two years. A filter life of one year is attained by the upgraded system's prefilters. The coalescer service life is about 4 to 6 months, whereby it is washable and reusable.

Filter Efficiency: The EMW® upgrade increased filtration efficiency in the filter house from 35% to well over 99%. Fouling of the gas turbines in the owner's power plant is now virtually nonexistent. On/offline washing has not been required since implementation of the upgrade in the year 2012.

The EMW® upgrade significantly boosted power output, reducing the average capacity loss over 6000 operating hours to only 0.8% per year as opposed to 3.0% with the old configuration. As noted above, a certain amount of capacity drop is related to ageing as opposed to fouling. The other (and larger) part of capacity drop, i.e. that caused by compressor fouling, was virtually eliminated on a lasting basis by the upgrade. The upgrade also reduced the average heat rate increase over a 12 month period to only 0.6% per year as opposed to 1.3% with the old configuration.

Providing increased power capacity and reduced fuel consumption, an EMW® filter system upgrade typically pays for itself within a few months' time. Besides these economic advantages, the upgrade offers yet another benefit "on top": reduced CO2 emissions.